Home Construction Management Job Costing For Construction

Job Costing for Construction: Everything You Need To Know

Job costing for construction is essential for accurate bidding and making a profit. In this article we cover how to calculate construction job costs.

You have a job to do tomorrow. How much will it cost? If you’re just estimating loosely based on your previous jobs, you’re probably missing out on a lot of revenue.

In construction, regardless of whether you are a general contractor or a specialty contractor, tracking and reducing costs is critical to profitability. Frequently, the market sets the price on your bid—and you need to be able to match your competitors. So the path to increased profitability better managing your costs and reducing them over time.

Construction job costing will help you also improve the accuracy of your future bids, while also giving you more control and awareness of your expenses.

What Is Job Costing for Construction?

Construction job costing is a method of tracking, assigning, and estimating costs on a project-by-project basis. Job costing traditionally includes labor, material, equipment, and other overhead costs.

Job costing is the alternative to process costing. Under process costing, you would provide an approximate estimate of how much something might cost you based on prior knowledge. You know that one job costs you $1,600, so doing a job half the size might cost you $800.

But when it comes to construction jobs, your labor, material, and equipment can break down in different ways. What if $1,000 of that cost was in a single piece of equipment that you’ll need either way? If that’s true, you will lose money on any job under $1,000.

How To Calculate Job Costing for Construction

Calculating job costing for construction begins with breaking down your project costs into specific expenses.

Let’s take a look at a very simple construction job cost for roofing:

| Simple Construction Job Costing – Roofing Job | |

| Labor | $7,500 |

| Materials | $5,750 |

| Equipment | $250 |

| Total Job Cost | $13,500 |

But the more accurate job costing for construction is, the more likely it is to be useful. A more detailed example would look like this:

| Detailed Construction Job Costing – Roofing Job | |

| Labor -Tear Down | $1,000 |

| Labor – Roof Prep | $2,000 |

| Labor – Installation | $3,000 |

| Labor – Labor Burden (25%) | $1,500 |

| Materials – Decking | $750 |

| Materials – Flashing | $500 |

| Materials – Underlayment | $200 |

| Materials – Shingles | $4,000 |

| Materials – Vents, Boots, Caps | $300 |

| Equipment – Rentals | $250 |

| Total Job Cost | $13,500 |

Based on the historic numbers, you can see that this roofing job will cost you around $13,500 in labor, materials, and other costs. And to be safe, you might add a 15% to 20% buffer around these costs, especially if material costs are rising in your area.

Catch budget overruns as they happen with Workyard

See How it Works

Breaking up your costs as above means that you can see exactly where your money is going. Calculating and estimating construction labor costs is particularly important given these costs can easily blow out of proportion if not managed carefully. Always be looking for cost savings, If you’re able to find asphalt shingles cheaper than $4,000, you can adjust your costs. If you’re able to avoid overtime, you can dramatically decrease your labor costs. You might conclude from the above that you aren’t leaving enough time for installation, leading to overtime pay being required to get the job done on time.

Construction Job Costing: Estimating Your Expenses

Job costing for construction breaks everything down into granular expense items. How you estimate those expenses matters. Often, an owner is doing everything right when it comes to their job costing—but their initial numbers are so far off that it doesn’t matter.

Labor

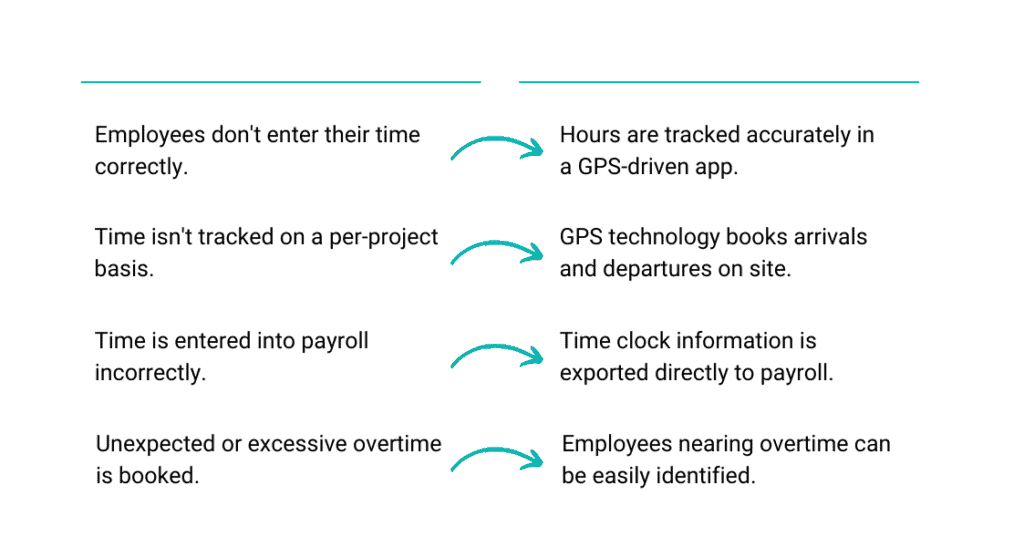

Construction companies can lose thousands of dollars to inaccurate labor estimates on every job. Employees enter their time incorrectly, mistakes occur during the payroll process, and scheduling issues lead to unnecessary overtime.

Construction company owners don’t have the time to micromanage their employees. If you aren’t on-site, you don’t know when your employees are actually arriving, when they leave, or when they’re taking breaks.

But Workyard can help.

With Workyard’s construction timesheet software, employee time is accurately tracked for each job site; additionally, employees can also tag hours to construction cost codes as part of their daily clock in and out process. Accurately capturing your labor costs for each job and being able to see how those costs are tracked in real-time helps you steer each project in the right direction to avoid overruns and improve your future bids.

“Workyard is going to save me $2,500 in inflated payroll costs from one guy alone. Guys would round to a 7 am arrival time. Now I can see 7:18, 7:14 actual arrival times on site.”

Dan HausmannOwner,

American Craftsman Contracting

Materials

In addition to labor, material costs can get out of control quickly. It’s not always easy to anticipate which materials will rise in cost, either. As supply chain issues become more common, contractors need to take action to reduce their uncertainty. This extends to job costing.

To make your job costing for construction more accurate:

- Cost out materials on a per-project basis rather than taking material costs estimates from previous projects.

- Insert wiggle room into project quotes, estimating a 10% to 20% material cost buffer depending on the market.

- Create contingencies early, such as alternative materials that can be sourced if the primary materials are too expensive.

Material costs can be volatile. But with proper construction planning and scheduling, they won’t break a project. Stay ahead of the game by keeping a comprehensive list of your vendors and frequently running material price comparisons.

Equipment Costs

Out of all job costs, equipment is probably the most straightforward. But there are still some ways a construction company can save money when calculating their equipment costs:

- Assess whether you can save money by leasing equipment rather than purchasing it or vice versa.

- Invest in equipment when it might improve the productivity of your workforce; an expensive piece of equipment may still be less than your cost of overtime.

- Ensure that your equipment is well-maintained and periodically inspected to avoid costly last-minute repairs.

Having the right tools and equipment matters—and so does maintenance. It’s all about running a tight ship even when you aren’t there.

Soft Costs

Construction hard costs are easier to focus on because they’re the ones that are the most obvious and directly associated with a project. By contrast, construction soft costs are more “passive” costs. For example:

- Inspection fees.

- Permits and surveys

- Architectural fees

- Bank fees

- Legal Fees

- etc..

The more soft costs you can directly associate with specific projects when job costing the better.

Having the right tools and equipment matters—and so does maintenance. It’s all about running a tight ship even when you aren’t there.

Job costing for construction is less about the process and more about having the right numbers. The more information you have available, the faster and easier the job costing process will be. Workyard can help.

Tips and Best Practices for Construction Job Costing

KPMG’s Global Construction Survey in 2015 discovered that only 31% of projects came within 10% of their budget. Job costing is difficult, even when you do everything right.

How can you make sure that your construction job costing is as accurate as possible?

| 1 | Use a GPS Time Tracking App Your payroll is your biggest expense. It has to be accurate. A GPS construction time clock app ensures that you’re only paying for hours actually worked—and that the hours worked are appropriately attributed by job so you know exactly where the money is going. |

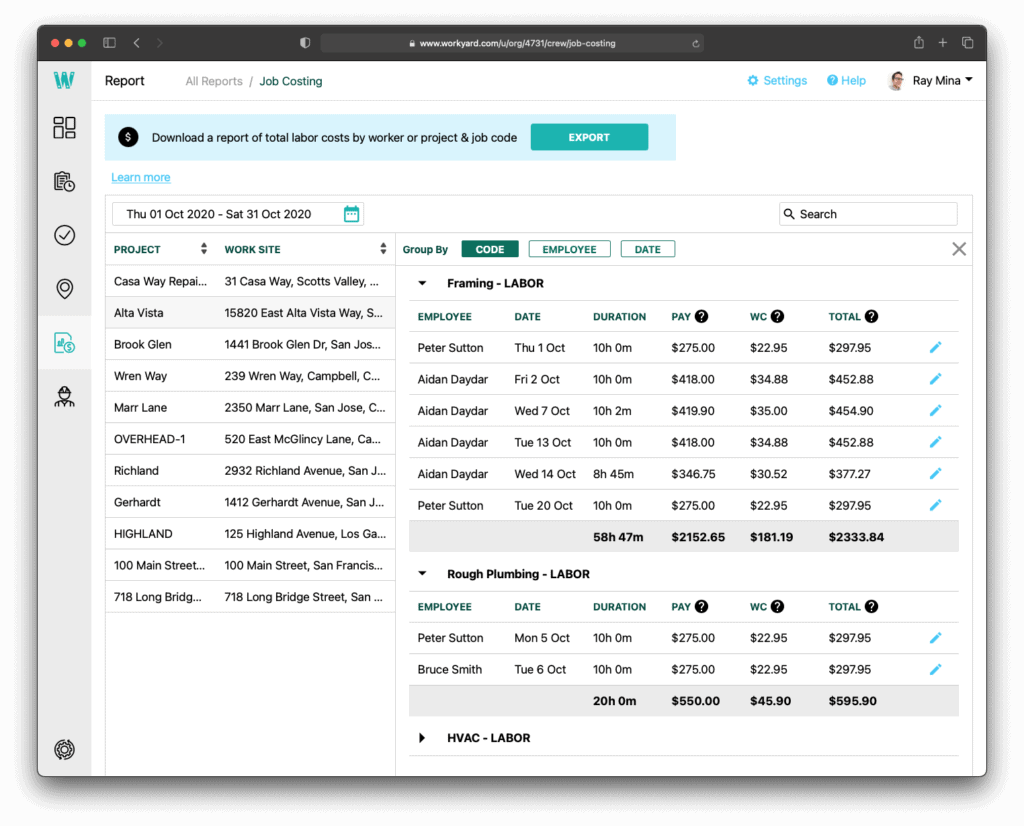

| 2 | Break Down Your Estimates & Use Cost Codes To Track Costs Accurately Breaking down your estimates not only helps you bid more accurately but also helps you pinpoint exactly which parts of a job you are underestimating or overestimating. Cost codes are a useful way to ‘bucket’ expenses for each piece of a job. Allocating time to specific cost codes can be cumbersome, but using a time tracking app designed for contractors will make this easier for your crew. |

| 3 | Accurately Calculate Your Labor Burden When Estimating Your labor burden provides an estimate of overhead associated with payroll. If you don’t calculate your labor burden, your labor costs won’t be complete—you’ll be spending significantly more than you think in overhead. Learn how to calculate your labor burden more effectively. |

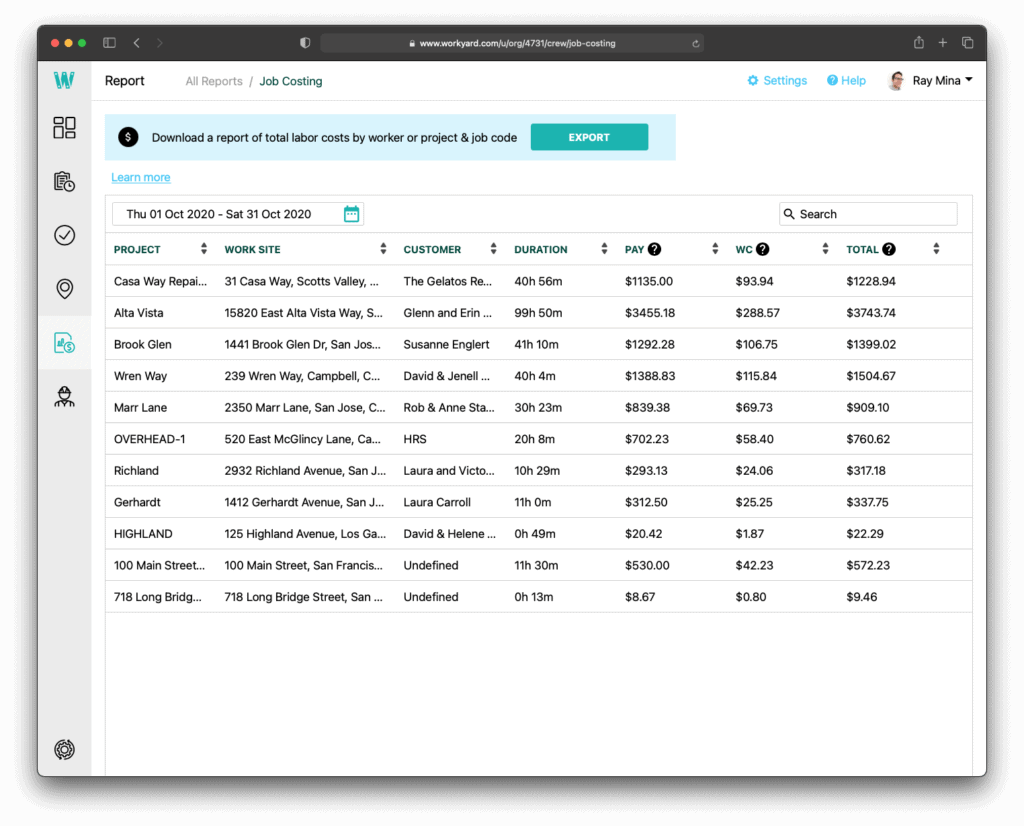

| 4 | Track Job Costs While The Project Is Executing Too many contractors wait until a project is finished to figure out whether they made money and to identify where exactly the overruns happened. Use real-time job costing software to have a live view of how your costs are tracking so you can steer your projects in the right direction. Get a live view of your job costs with Workyard’s job costing software. |

| 5 | Monitor Your Client BillingsReimbursable costs must be reimbursed, otherwise, your company is losing money. But often client billings aren’t accurate because the costs aren’t being captured or correctly attributed. Workyard makes it possible to assign payroll and other expenses directly to projects, increasing client reimbursements. |

| 6 | Leverage Job Cost Reports From Previous Jobs To Improve Future Bids Workyard provides labor cost reports for past projects broken down by employee and code. |

What To Look for in a Construction Job Cost Report

Accurate job costing for construction requires a strong foundation. With the right data, your company will be able to calculate job costs with greater levels of accuracy. Workyard offers a job cost report that gives you the most accurate breakdown of your project labor costs. Additionally, it will automatically update the job cost report every time a new timecard is submitted, which ultimately helps inform decisions that increase profits.

“I like that I can instantly run a report in Workyard to show me how we’re doing across any of the 5 projects we’ve got running at the same time.”

Kristi MillerOwner,

Eric Miller Electric

Streamlining Your Job Costing with QuickBooks and Workyard

For construction professionals looking to improve the accuracy of their job costing, using QuickBooks Time Tracking is a great way to allocate expenses correctly and maintain control over project budgets. The software can be integrated with Employee Time Tracking solutions, like Workyard, to easily log hours worked and ensure that every expense is properly tracked.

Accurately capturing your costs is fundamental for understanding your job profitability. With Job Tracking in place, construction companies can see a real-time overview of how expenses are shaping up throughout the life of the project. Workyard makes this process seamless by providing precise job-level data, which can then be directly synced with your QuickBooks account.

If you want to maximize the value of your Construction Time Tracking efforts, you should also integrate your time data with your payroll system. Workyard’s Payroll Integration allows you to push hours tracked and labor costs to your payroll provider, streamlining your payroll process and ensuring accuracy.

For those using a Time Clock App, it’s important to have one that ties together location-based tracking with job costing. By tracking GPS data, you can ensure that the hours worked are correctly tagged to each project, and that travel between job sites is accounted for.

Beyond labor, your equipment and material costs also need to be closely monitored. Workyard makes it easy to see a breakdown of labor hours and related costs for each Job Cost Report. Detailed job costing reports give you the necessary insights to manage your projects more effectively and bid more accurately for future jobs.

For real-time updates, you should consider using Time Tracking Integrations that link directly with your accounting software. These integrations allow you to see a live feed of how your costs are tracking and ensure all your data is up-to-date without manual entry.

Finally, when managing all your projects and employee hours, a comprehensive Employee Time Clock solution like Workyard gives you an edge. It enables you to easily assign hours to the correct projects and cost codes, ensuring that your job costing is precise and your profitability is protected.

By using these tools in conjunction with each other, you can have a better understanding of your costs, streamline your processes, and ensure that you’re bidding accurately on each construction project.

How To Get Started With Job Costing

To get started with your job costing today, sign up for a free trial of Workyard. Workyard will help you narrow down your payroll expenses to the minute, reduce your overtime, and track labor costs accurately for each of your projects.

Workyard makes it easy to capture job costs and improve profitability by:

- Correctly assigning time to each project by detecting precise arrival and departure times

- Enabling your crew to easily tag hours to specific cost codes

- Automatically capturing and assigning mileage and driving time to the relevant project

- Seeing project and labor costs in real-time

- Providing construction profitability analysis and a historical data set you can reference for future project bids

Not only will you have the historical data that you need to produce accurate job cost reports but also the real-time access you need to control expenses once on the job.

Job order costing provides granular information about exactly how much a job should cost. Through job costing for construction, companies can increase their profit margins and avoid cost overruns.

Job costing for construction is much more accurate than process costing. Despite this, many small contractors use process costing because it’s simpler and easier. Between the two, job costing will provide far more accurate estimates.

Process costing is a simpler, streamlined method of costing a project that is usually used to estimate larger-scale projects. For instance, on average, a roof costs $x to install, but job costing digs deeper into granular costs to provide accurate projections.

Accurate job costing enables construction businesses to identify the true cost of each task, leading to better budgeting, resource allocation, and pricing strategies. By understanding job costs, businesses can set competitive prices while ensuring profitability. It also helps identify cost overruns and inefficiencies, allowing for adjustments in future projects. Accurate job costing can lead to improved profit margins by reducing waste, optimizing resource use, and helping construction companies understand which jobs are most profitable, guiding them toward more lucrative opportunities.

Implementing job costing for construction can face challenges such as accurately tracking labor hours, managing fluctuating material prices, and handling overhead allocation. Manual data entry errors and inconsistent reporting methods can lead to inaccurate cost data. Also, lack of real-time tracking can delay decision-making and obscure current project profitability. To overcome these challenges, construction companies often adopt specialized software that automates data collection, integrates with time-tracking tools, and offers transparent cost breakdowns for effective job costing.